Product Description:

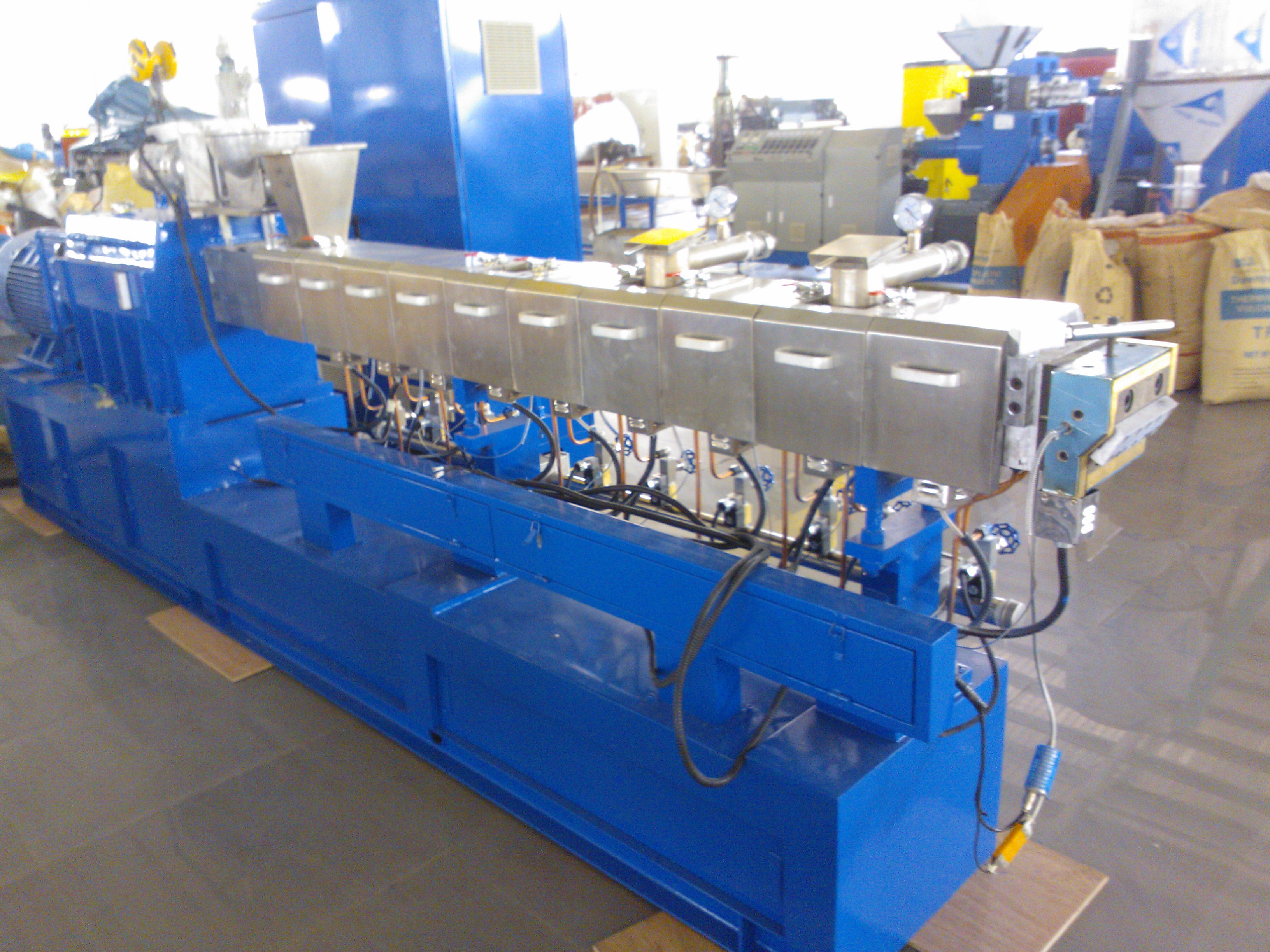

The Recycling Washing and Pelletizing Machine is a kind of advanced compounding pelletizing equipment made of PP twin screw extruder, which is certified with CE certification. This machine is featured with PLC control system, and can be paid through T/T or L/C. Its weight is 3000kg, making it ideal for different production sites.

The machine can be used for PP/PE/ABS/PS/HIPS/PVC material compounding and pelletizing, and can be customized according to customer’s requirements. It is characterized by high output, energy saving and high automation. Also, it features high torque transmission for stable and reliable operation.

The Recycling Washing and Pelletizing Machine is used for recycling, washing, and pelletizing of PP/PE/ABS/PS/HIPS/PVC material, making it ideal for both commercial and industrial use. It has a compact design and high performance, making it a cost-effective choice for your plastic compounding and pelletizing needs.

Features:

- Product Name: Recycling Washing and Pelletizing Machine

- Warranty: 1 Year

- Power Consumption: 120kw

- Size: 3000*1800*2000mm

- Power: 380V/50Hz/3Phase

- Weight: 3000kg

- PP twin screw extruder

- PP twin screw extruder

- Caco3 filler extrusion

Applications:

YAOAN’s AF-72 Recycling Washing and Pelletizing Machine is a high-performance product that features air cooling and PP twin screw extruder. It is designed for recycling and washing multiple kinds of plastic materials, which is reliable and efficient. It adopts PLC control system and has a capacity of 300-1000kg/h. The size is 3000*1800*2000mm. It is CE certified and the payment terms are T/T, L/C.

The Recycling Washing and Pelletizing Machine can be applied in various scenes, such as plastic film recycling, agriculture film recycling, woven bag and big bag recycling, plastic bag recycling, plastic bottle recycling, plastic drum recycling, plastic board and plate recycling, plastic cup and tray recycling, plastic pipe recycling, etc. It is highly efficient and can process large amount of waste materials quickly. The washed and pelletized products are of high quality and can be used for further production.

Technical Parameters:

| Name |

Parameters |

| Power |

380V/50Hz/3Phase |

| Size |

3000*1800*2000mm |

| Delivery Time |

30 Days |

| Payment Term |

T/T, L/C |

| Certification |

CE |

| Capacity |

300-1000kg/h |

| Control System |

PLC |

| Warranty |

1 Year |

| Weight |

3000kg |

| Product Name |

Compounding Pelletizing Machine |

| PP Twin Screw Extruder |

Yes |

| Twin Screw Extruder |

Yes |

| Caco3 Filler Extrusion |

Yes |

Support and Services:

Recycling Washing and Pelletizing Machine Technical Support and Services

We provide a range of technical support and services for our Recycling Washing and Pelletizing Machine. Our team of experienced technicians will work with you to ensure that your machine is running efficiently and that any problems are resolved quickly and efficiently.

We offer a comprehensive range of services including:

- Installation and commissioning

- Operational and maintenance training

- Regular preventative maintenance and service

- Upgrades and modifications

- Spare parts and consumables

- Troubleshooting and fault finding

Please contact us for further information about our Recycling Washing and Pelletizing Machine technical support and services.

Packing and Shipping:

Packaging and Shipping for Recycling Washing and Pelletizing Machine

Recycling Washing and Pelletizing Machine should be packaged and shipped in the following manner:

- The machine should be securely packed in a wooden box to protect it from damage.

- The box should be loaded onto the shipping truck with a forklift.

- The truck should be driven to the designated delivery address with all necessary safety precautions.

- The machine should be unloaded and set up at the delivery address.

FAQ:

- Q: What is the brand of the Recycling Washing and Pelletizing Machine?

A: The Recycling Washing and Pelletizing Machine is made by YAOAN.

- Q: What is the model number of the Recycling Washing and Pelletizing Machine?

A: The model number of the Recycling Washing and Pelletizing Machine is AF-72.

- Q: What is the origin of the Recycling Washing and Pelletizing Machine?

A: The Recycling Washing and Pelletizing Machine is made in China.

- Q: What kind of material can be processed by the Recycling Washing and Pelletizing Machine?

A: The Recycling Washing and Pelletizing Machine is suitable for processing plastic waste, such as PET bottles, PP/PE films, and other plastic materials.

- Q: What is the capacity of the Recycling Washing and Pelletizing Machine?

A: The capacity of the Recycling Washing and Pelletizing Machine is up to 500kg/h.